Designed by real sailors.

Masterminded by a world-class naval architect.

Shaped by Experience

After 11 years at sea and roughly one and a half circumnavigations, one lesson became clear: offshore sailing isn’t about peak performance in ideal conditions. It’s about sustaining high average speeds with a fully loaded boat, a short-handed, tired crew, and conditions that are rarely clean or predictable.

Over time, it also became clear that many boats sail well when lightly loaded and in flat seas. Far fewer are designed to carry real cruising loads without sacrificing speed, control, or confidence.

Introducing the

NAHOA M

The Brief

Nahoa M is the first model in the Nahoa Yachts range. It defines the platform on which future models — Nahoa L and Nahoa S — will be built, each scaled deliberately but guided by the same offshore-first design philosophy:

The design brief was clear: maintain high average speeds with a full cruising load, remain controllable and predictable in messy offshore conditions with a short-handed crew, and stay simple enough to operate and maintain far from supply chains and shore-side support.

The interior volume is deliberately restrained to that of a cruising 48-foot catamaran, keeping systems compact, accessible, and easy to live with over time. The rig is sized and loaded like a 52 — manageable by a short-handed crew, predictable in squalls, and conservative in its loads.

The hulls carry true expedition loads without penalty, while the long, efficient waterline delivers the high average speeds more typical of a 57-foot platform.

At the core, the boat had to inspire confidence — a platform that feels like a fortress when conditions deteriorate, not a liability to manage.

“We want to go anywhere..”

We didn’t design this boat around a destination or a season.

Real freedom is being able to put your finger on a map and say, “we’re going there” without second-guessing the boat.

The Nahoa M gives us that freedom.

Design Philosophy

Every decision comes back to three things: Simplicity, Strength and Safety.

Simplicity breeds confidence. Intuitive systems reduce dependence on specialists and shore-side support. When something does go wrong, you can understand it, fix it, and keep moving — even in the most remote places.

Strength comes from aluminum — a material proven by decades of ocean miles. It’s repairable anywhere on earth, and it doesn’t just survive the unexpected; it invites you to go looking for it.

Safety is built into every design and outfitting decision - from watertight bulkheads to the absence of through-hulls in accommodation spaces.

Technical Overview

Design & Construction

Naval Architect: Pierre Delion

Construction: Marine Grade Aluminum

Certification: ISO Category A (10 persons)Dimensions:

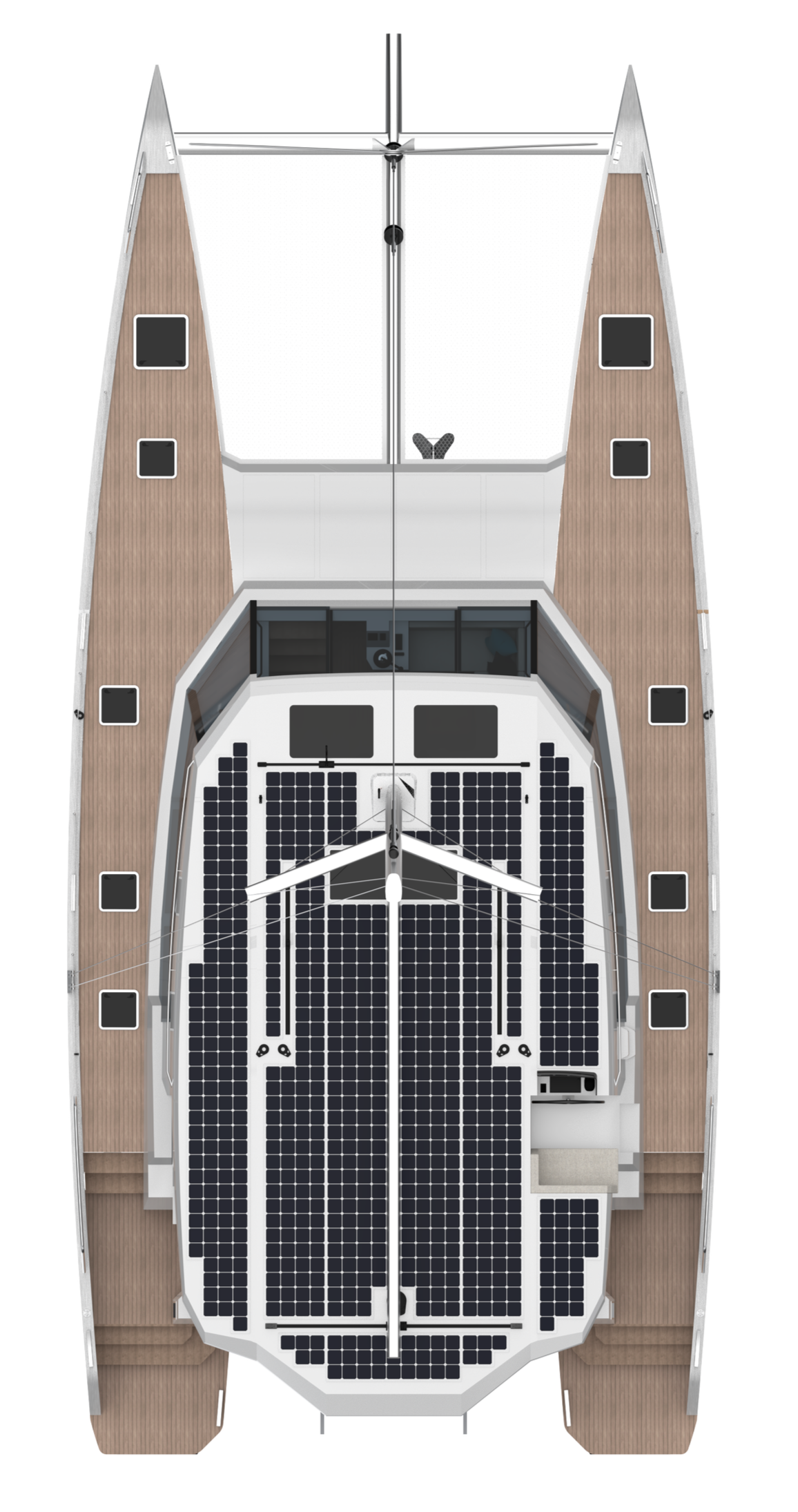

Length Overall (LOA): 17.4 m 57 ft

Beam: 8.3m

Draft: 1.55m

Propulsion & Systems:

Engines: Twin 80HP Diesel

Drive: Shaft with V-Drive

Fuel Capacity: 1,800 L

Solar Capacity: 5 kW+

Performance:

10-12 knot boat speed in typical Trade Wind passages enabling 200+ nautical mile days

Why Aluminum

Sailing around the world is a monumental task, from navigating foreign waters to procuring broken parts; it’s a full-time job and more. Nahoa Yachts was born from all the lessons we’ve learned over the past ten years and 50,000+ nautical miles from our first circumnavigation.

Aluminum is the ultimate material for long-range, expedition-style cruising yachts due to its exceptional strength-to-weight ratio, corrosion resistance, and ductility (deforms before it breaks). Unlike fiberglass, aluminum doesn’t require constant polishing, and deck hardware such as cleats and stations are welded on, eliminating leaks from above.

Maintaining a boat is a constant, but aluminum significantly minimizes those efforts. Most great expedition vessels are still built in aluminum to this day.

Carbon Fiber

Upon impact, carbon fiber tends to splinter, creating sharp, jagged edges. This splintering can compromise the structural integrity of the hull. Despite its strength, the brittleness of carbon fiber means it can be more susceptible to catastrophic failure when subjected to high-impact forces.

Fiberglass

When impacted, fiberglass tends to crack and can develop a network of fractures radiating from the point of impact.

Aluminum

Aluminum hulls are extremely ductile, allowing them to absorb and distribute impact forces effectively. Instead of cracking or splintering, aluminum hulls typically deform, showing dents and bends rather than punctures.

Ductility (noun): The ability of a material to undergo significant plastic deformation before rupture, often characterized by its capacity to be stretched or bent without breaking.

Quality & Certification

The Nahoa M is designed in accordance with ISO rules and CE certification requirements governing stability, buoyancy, and watertight integrity. Given its role as an expedition-style catamaran, the design intentionally exceeds minimum certification standards.

Interested in a Nahoa M?

Designed by real sailors. Masterminded by a world-class naval architect. Built by the best.

© 2026 Sailing Nahoa. All rights reserved.